Finishing the press - the details that make the difference

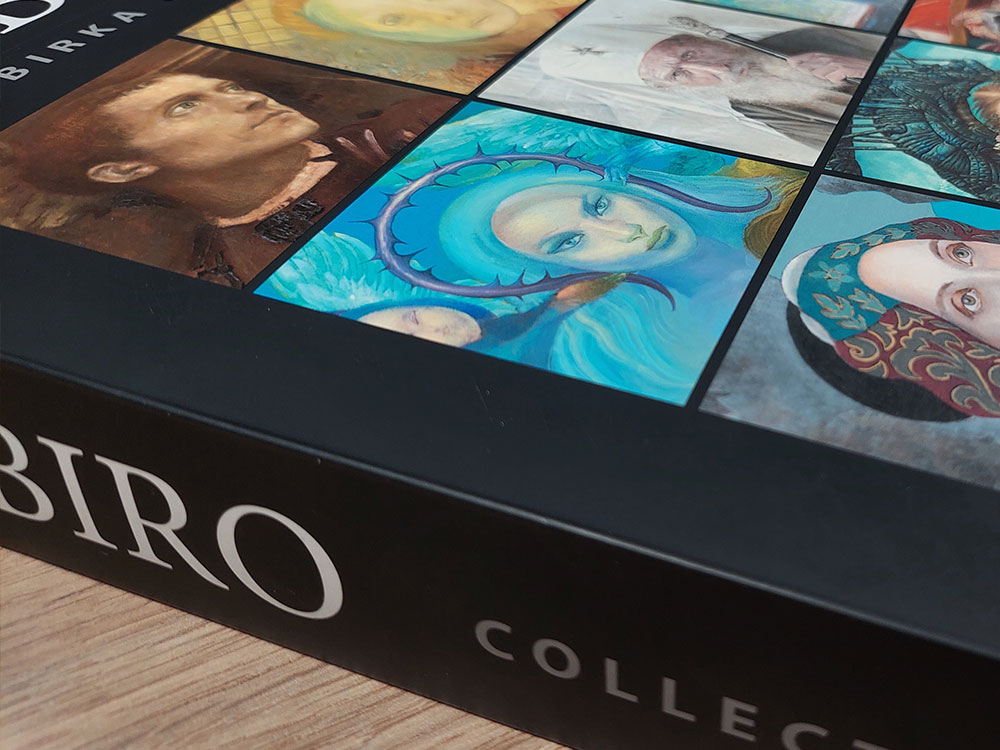

Finishing processes are a key step in turning printed material into a final, professionally designed product. At BiroGRAF, we have a complete plant of automatic machines for folding, gluing, sewing, stapling, plasticizing, hard binding, stamping and special effects.

This comprehensive system allows us to realize even the most demanding projects with top quality, stability and aesthetic perfection.

Finishing techniques we offer

Relief printing (blindruk / emboss / deboss)

UV varnishing (selective UV and 3D UV)

- Selective UV varnish - emphasizing certain elements (titles, images, logos)

- 3D UV varnish – a raised, tactile glossy effect

Finishing techniques

- Plasticization - Protection of printed material with a matte or glossy layer.

- Gold and silver printing – Premium effects using foils in various colors.

- Relief printing – Highlighting the design with three-dimensional effects.

- UV varnishing – High gloss and protection of certain design elements.

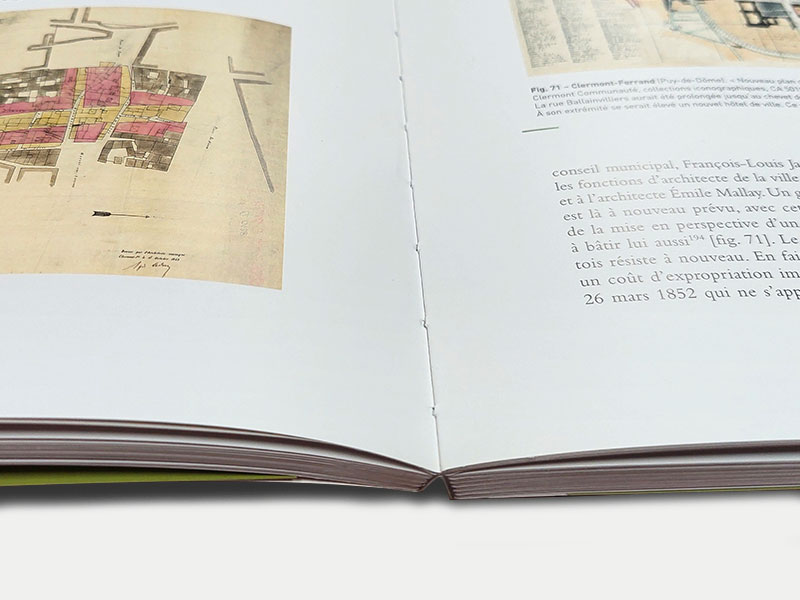

- Sewing and binding - Books, catalogs and brochures gain longevity and stability.

Sewing, stapling and binding

- Clamming – for brochures, magazines and catalog formats.

- Thermal bonding (glued binding) – an elegant and practical solution for books and catalogs.

- Finished sewing – the longest-lasting and highest-quality way of binding.

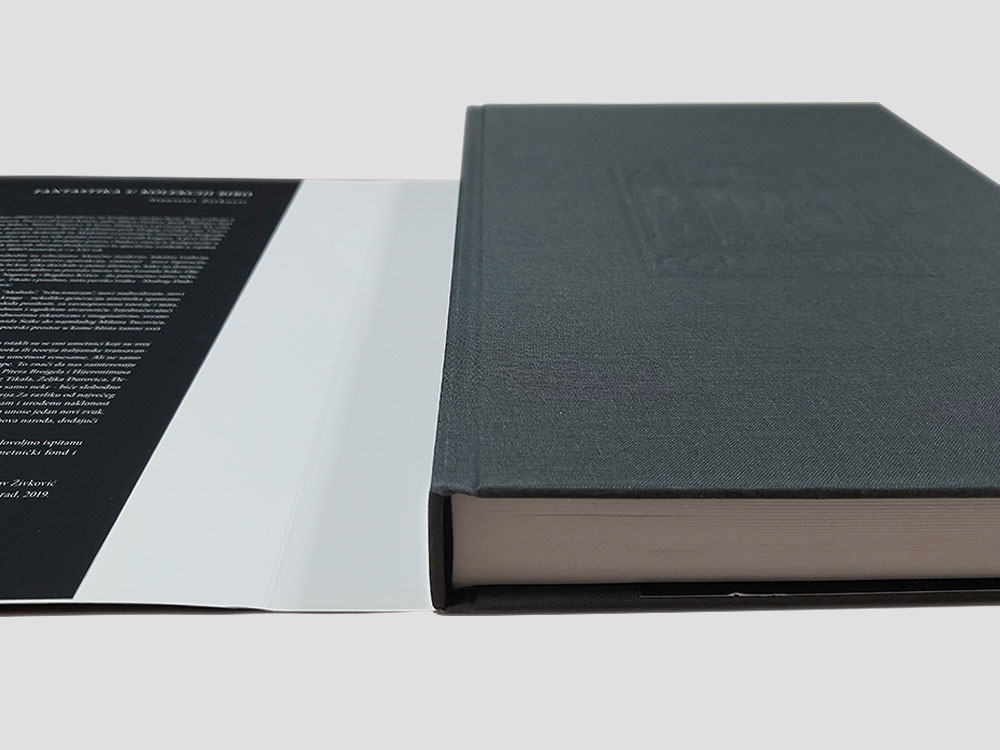

- Hardcover – books, monographs and luxury editions.

- Spiral (wire-o) – notebooks, calendars and manuals.

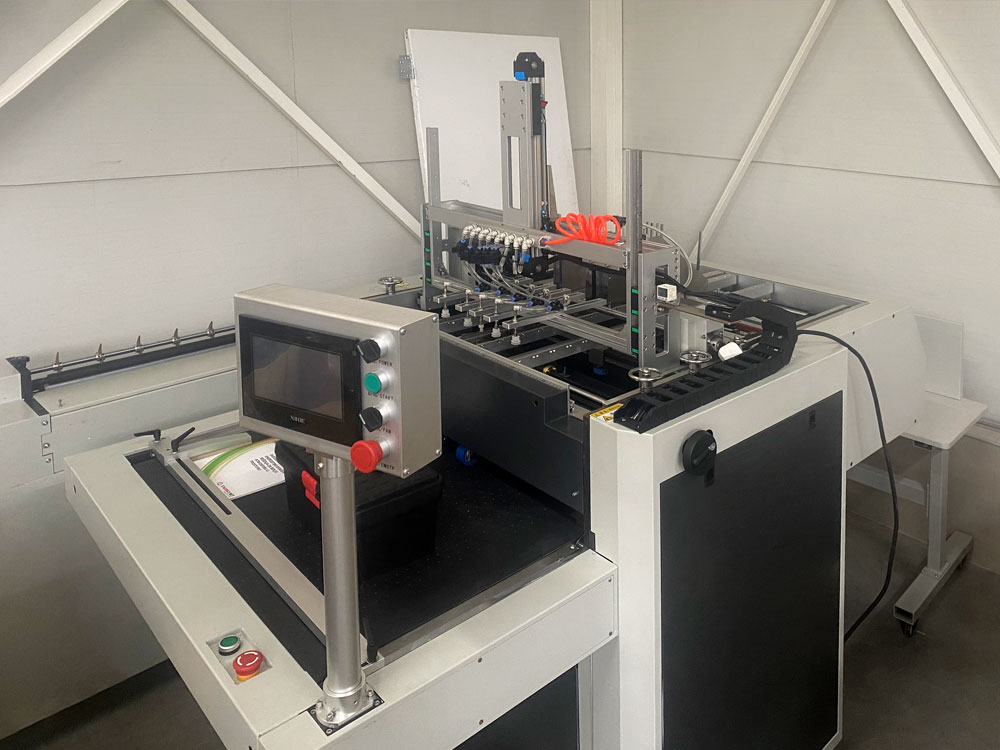

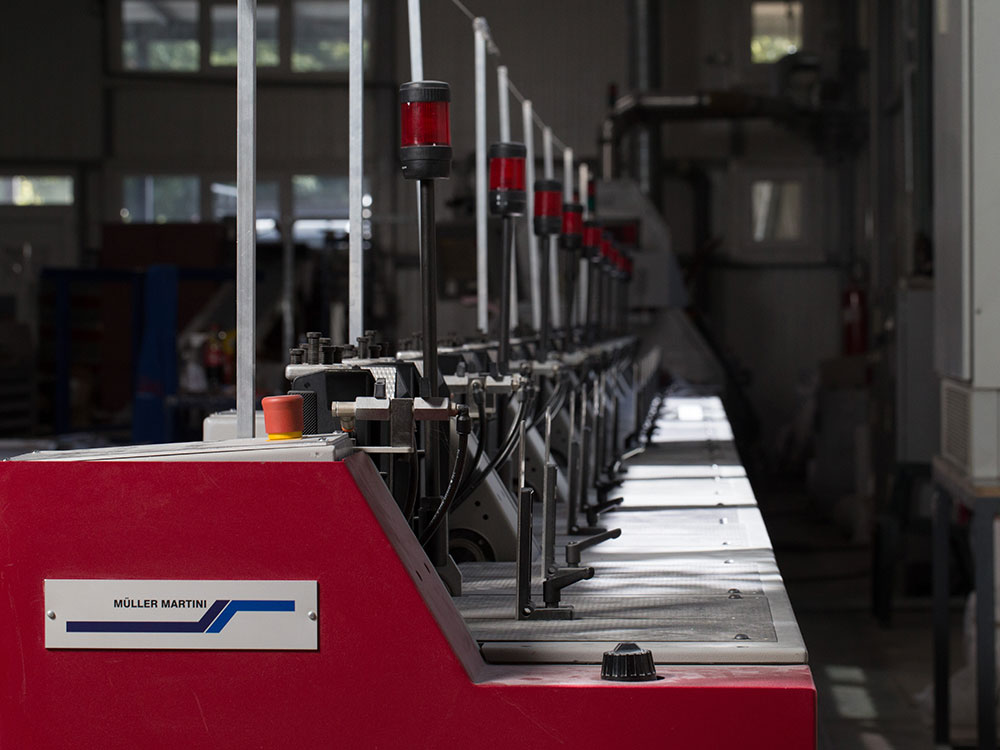

Equipment for the finishing sector

- MBO KT 760 / F 530 – B1 and B2 format bending machines, high speed and precision.

- Horizon Stitch Liner 5500 – automatic stapling line, ideal for magazines and brochures.

- Muller Martini Acoro A5 – complete line for paperback and automatic cutting on three sides.

- Keqiang ZFM 9A and Ferrari – machines for making hard covers, manual and semi-automatic versions.

- Folio Taurus 760NG – laminator with vacuum system, for plasticizing luxury materials.

- Perfecta 115 SE and Wohlenberg – precise industrial knives for cutting and finishing.

- Kerma and Heidelberg die cutting machine - machines for stamping packaging and special forms.

Specialized equipment for manual finishing:

- HD Horde ZTC 1000C - laminating machine (gluing printed paper to cardboard).

- Schmidt – a manual machine for inserting a book block into a hard cover.

- Cougar - machine for rounding the book block for hardcover.

- Protocol – a machine for manual stapling of large formats.

Additionally, the finishing sector includes equipment for sewing book blocks (Aster Pro, Meccanotecnica Universe), insert cover sheet (Hunkeler V1 A52OKS) and cover branding (Pra Form), which ensures the complete process - from the test print to the finished book, with consistent quality control at every stage.

In addition, the finishing sector includes equipment for sewing the book block (Aster Pro, Meccanotecnica Universe), inserting the front sheet (Hunkeler V1 A52OKS) and branding the cover (Pra Form), which ensures the complete process - from the test print to the finished book, with consistent quality control at every stage.